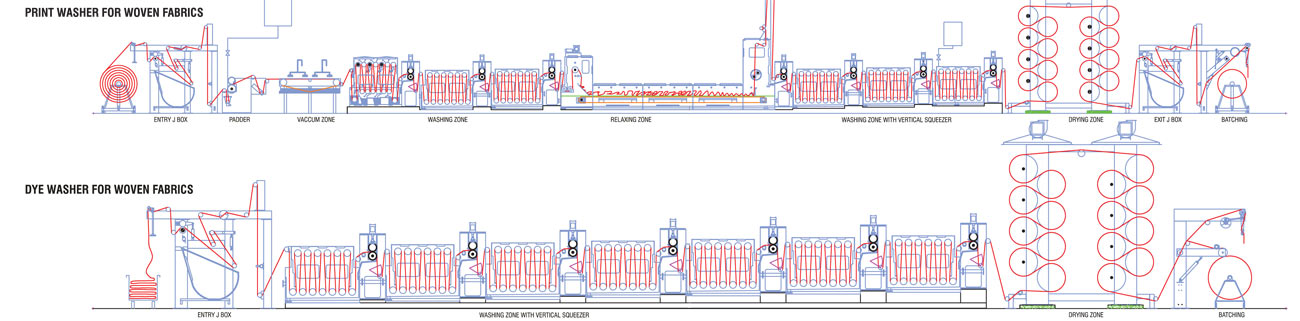

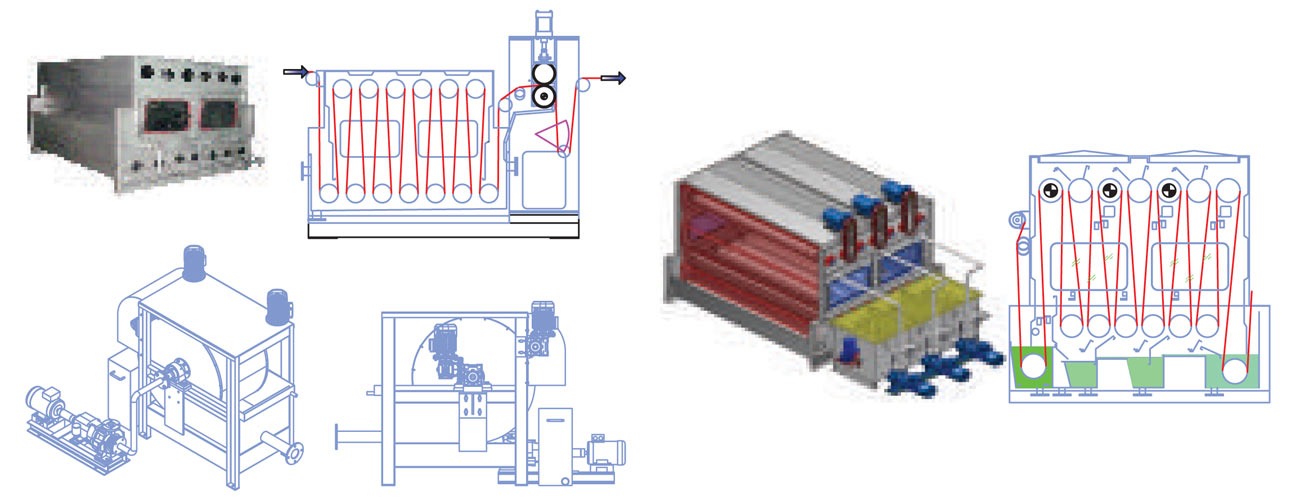

Enclosed STAINLESS STEEL (304 & 316) tank with internal partitions for serpentine flow and better washing efficiency.

S.S. make 193 mm dia guide rollers.

Large four glass doors for easy threading and cleaning.

Circulation pump and filter for each wash box. Separate direct and indirect steam heating system with temperature control by PLC.

Heavy constructed Nip after each wash box from mild steel/stainless steel pneumatic type compensator for synchornisation, bow roller before nip and directly couple geared motor with AC invertor drive. Linear pot is provided for better and fine synchronisation control between washing compartments.

Continuous high efficiency rotating drum type filter with circulation pump. This filter continuously cleans the liquor and sludge is removed out in basket.

Stationary type basket filters with circulation pump. This filter is used for subsequent washing compartments where fluff level is less and baskets are manulally removed and cleaned at regular intervals.

Steam tight stainless steel construction.

Separate 3 liquor troughs with counter flow arrangement & individual drain.