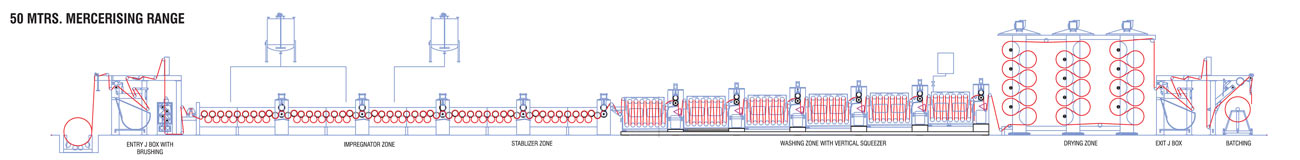

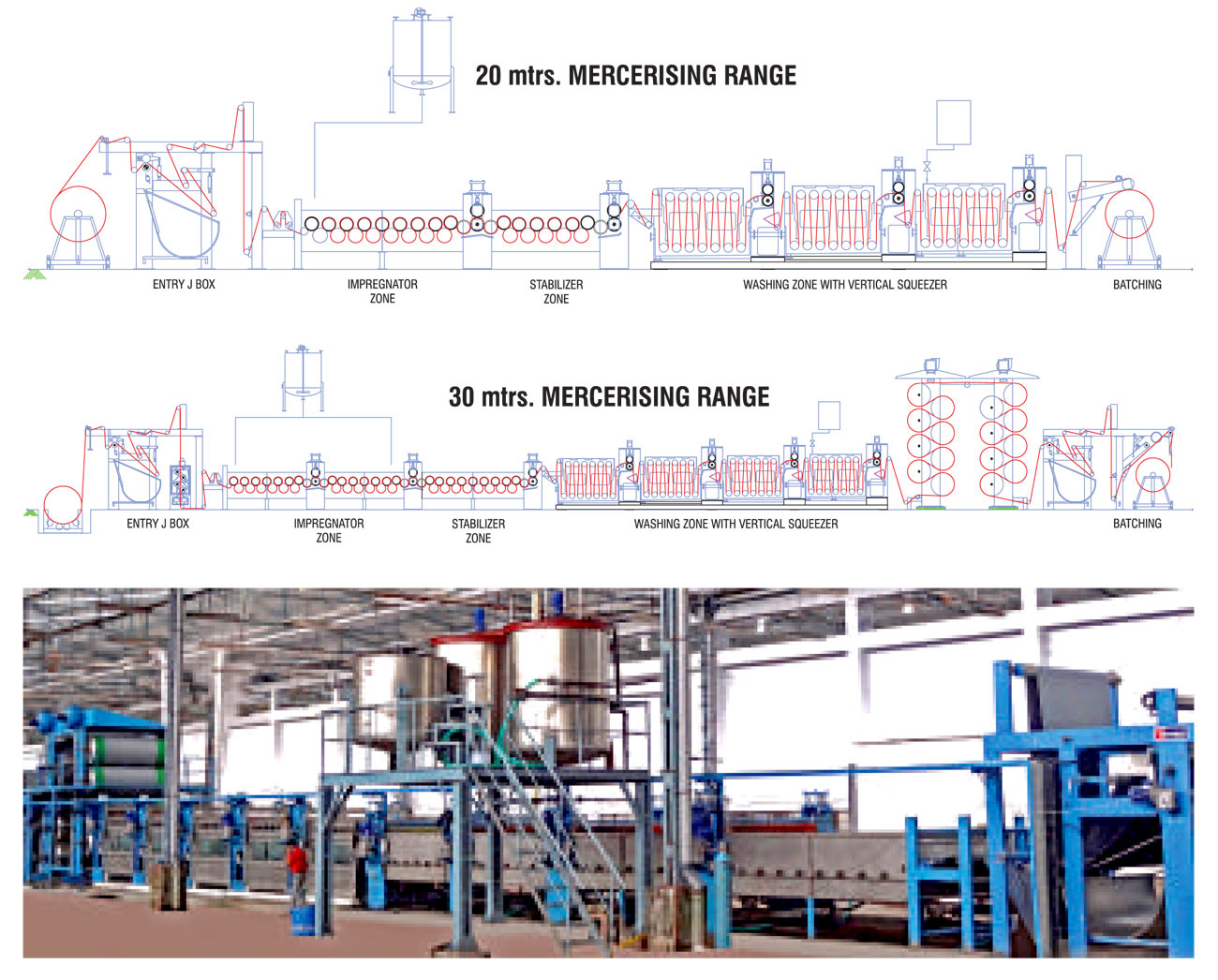

Purposes of Mercerising is to give the dimensional stability to heavy or light quality of fabrics by passing for certain interval through the caustic zone called IMPREGANTOR, then STABILIZER and followed by intensive washing and drying.

Use of ROLLER BED TECHNOLOGY in Impregnator and Stabilizer zone

When fabric gets in contact with caustic, reaction starts immediately & fabric started loosing it dimensional stability & started to shrink in length as well as width.

During contact time in IMPREGNATOR & STABILIZER of 30 to 60 SEC, it is necessary that fabric keeps in continuous contact with the rollers instead of being contactless in open or free air Then reaction of shrinkage is much faster.

Due to roller bed there is not any chance of open or free air contact with fabric. It helps to avoid minimum shrinkage in the fabric & help to give better dimensional stability.

Wet on Dry mercerising

Wet on wet mercerising

IMPREGNATOR - BOMEN control by highly advanced technology to get require concentration to avoid unwanted CS in the fabric & excess wastage of caustic.

STABILIZER - Controlled utilization of week lye on the fabric by minimum addition of fresh water to get control on consumption of water.

By above both the parameters very easy to minimise the operational cost of CAUSTIC, LYE, ACETIC ACID, WATER & STEAM.

No reprocessing as not any chance of CS in the fabric.

Better dimensional stability with improved LUSTURE.

Require DYEING, PRINTING & FINISHING quality is easily achievable.

STAINLESS STEEL tank for impregnator and stabilizer.