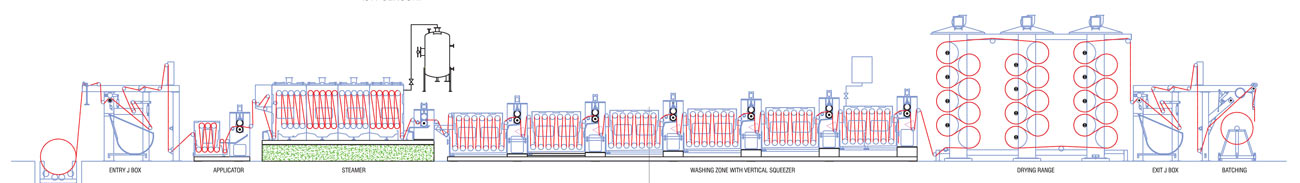

YAMUNA has manufactured with highest technology for CONTINUOUS PRE TREATMENT DESIZING AND OVER DYEING RANGES to solve the following purposes.

To remove unwanted sizes like PVA to STARCH with the help of ENZYMES. A special applicator being used before tight stand steamer for development and high efficiency washing compartments to be followed.

Suitable for various dyeing called REACTIVE, VAT, SULPHER, DYES etc. with the help of technology of deflection control rollers gives even squeezing throughout the width. After passing through steamer travels to the high efficiency washing compartments to be followed.

Desizing chemicals applicator is designed with a longer dwell time (4mtr fabric traverse path). This allows enough time for application on the fabric especially for heavy weights.

The applicator is provided with continuous dosing of chemicals by automatic level control system.

Effective Dosing system gives accuracy to send require Dyes & Chemicals to the APPLICATOR.

Indirect & direct steam heating with temperature control is provided and can be used on demand of the application and the process.

Continuous rotary type filter is provided for keeping the liquor always clean during application.

For Overdyeing, low liquor trough with single guide roll is provided to minimise the dye liquor wastage on changeover.

Optionally, hydraulic deflection controll rollers are provided in the squeezing nip for uniform dye liquor application.

J-BOX unit in entry and exit for continuous production

Steam heated cylinders unit for drying purpose.