CURING / POLYMERISER

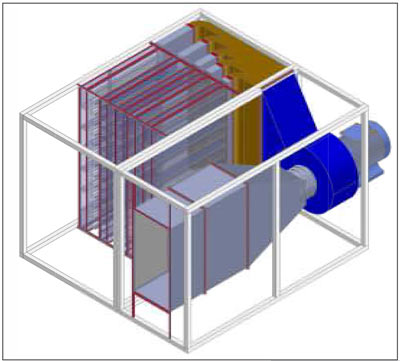

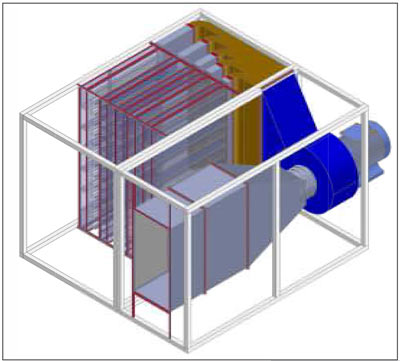

CURING MACHINE - POLYMERISER

- Suitable for drying & Curing dryed / coated fabrics and for special finishing ranges.

- Roller Face : 1600 - 4400 mm

- Roller Diameter : 140/178 mm (Mild Steel, epoxy coated or SS)

- Centre to Centre distance : 1100 / 1500 mm

- Heating Media : circulating Oil, Steam or gas fired.

- Drive : A.C. invertor drive to top rollers.

- Separate blowers for top and bottom air nozzles.

- Uniformity in temperature, width wise, length and diagonally.

- Nozzles Slit type, air flows through between rollers, flow adjusted by VFD.

- Modular construction each section contains 50 mtrs. (Tailor made sections can be designed on request)

- Brake system for bottom rollers for cleaning can be provided.

- Fabric residual moisture controller, Chamber Humidity controller can be provided.

- Supplied as independent machines with padding and plaiting batching or in conjunction with continuous processing machines.

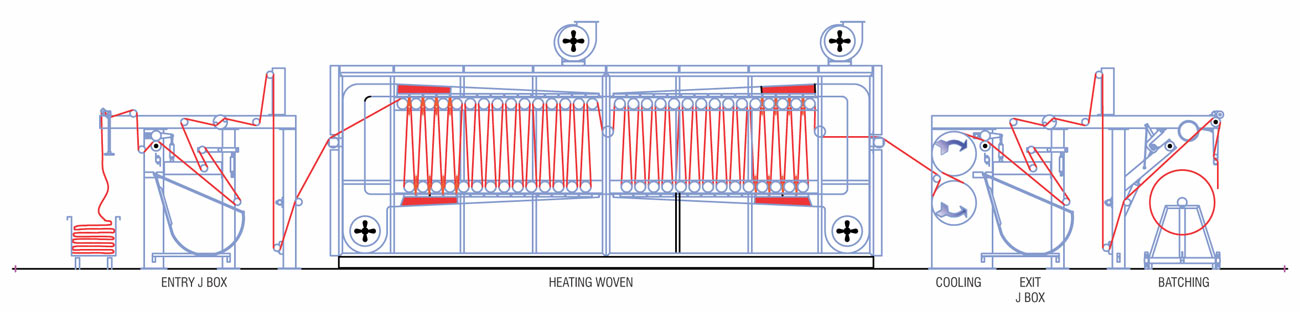

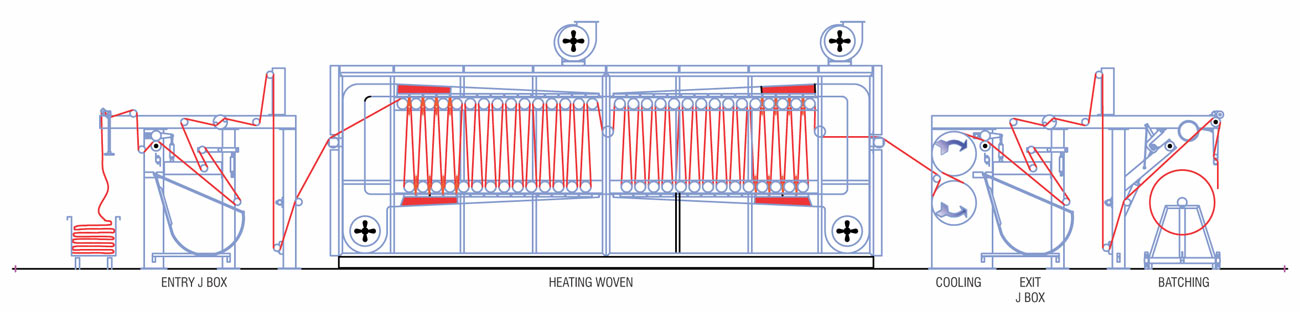

VERTICAL DRYER – DIPPING MACHINE

Dipping Lines for nylon & polyester fabric for tyrecord fabrics, belting and canvas are supplied with vertical dryer and Stenter. Vertical dryer are either 2

pass or 4 pass. Each pass can have either impingement of air on 1 side or on both sides.

Slit type nozzles are provided for uniform air pressure and temperature. This can be provided with oil heating or direct gas fire. Central exhaust system is

provided through and within vertical dryer, which can also be used for quick pool.